About the Case Study _

Benefits for the customer and end-users:

- High quality firmware developed with the state-of-the-art technologies.

- No syntax bugs and errors once the code is compiled thanks to Rust Language.

- Saved future hiccups through Software and Firmware expertise during the early stages of product development.

- High-pace turnaround between providing features for prototype testing and finishing them to the deployable state.

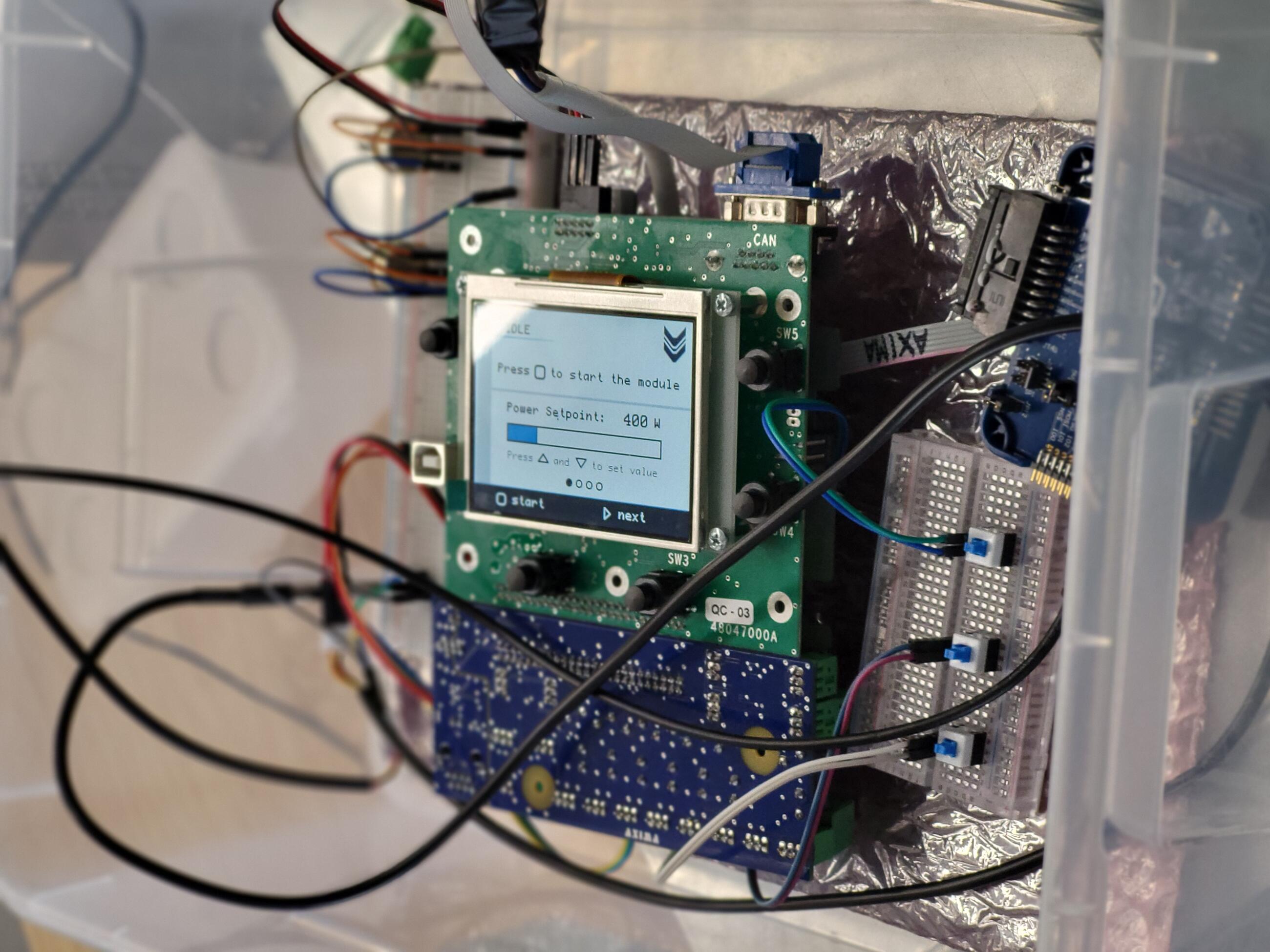

LeanCat Water Electrolyzer module is a standard rack 6U hardware box for lab and or industrial H2 production. The system is interconnected with the master system which is able to manage several racks of water electrolyzer modules based on customer requirements. The electrolyzer itself is a fine piece of technology which requires precise management of its internals due to its a bit fragile nature.

The hardware platform is industrial MCU responsible for running the firmware. The firmware itself takes care of managing electricity input to the electrolyzer stack while maintaining position of valves and sensing values from several physical sensors.

We have come very early into the development of WE module hence we were able to support LeanCat not only by providing well tested piece of firmware software but also with a lot of custom one time used development code which was required by the customer to aim with the module hardware development. This in fact very agile cooperation done in a truly start-up manner saved a lot of time and money on the customer side firstly due to no need to provide us with well specified and well finished module hardware for the firmware development and secondly also by providing quite a lot of additional code used solely for the purpose of the hardware development itself.

Technologies used:

- STM32 F4 MCU

- 2.8” LCD display

- Dallas/Maxim temperature sensors

- Conductivity sensors

- Pressure sensors

- Valve actuators

-

Hardware box

-

Involving high school students in the development

-

UX UI team solving wireflow