Automated preparation of electron microscopy samples

Ion cannon, electron beam, welding onto a needle tip... It may sound like science fiction but these are everyday terms for people working with the AutoTEM application.

Customer

Competences

Technology

About the Case Study _

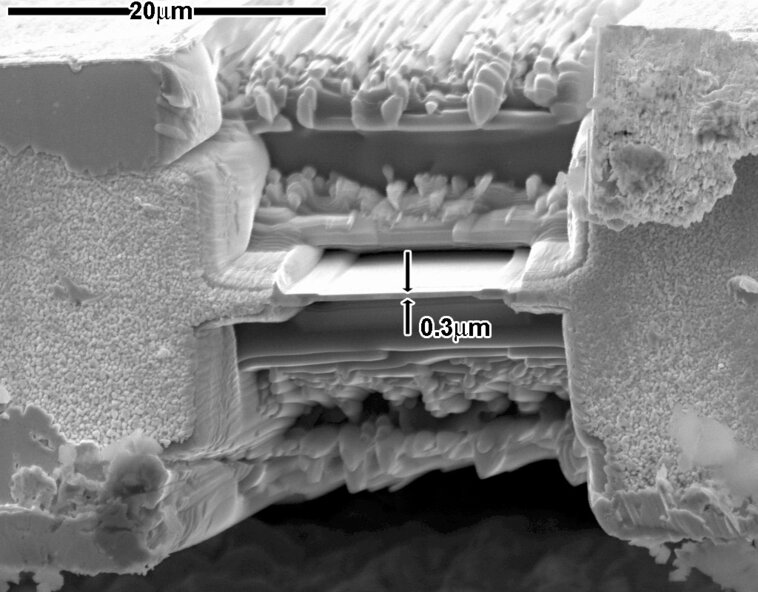

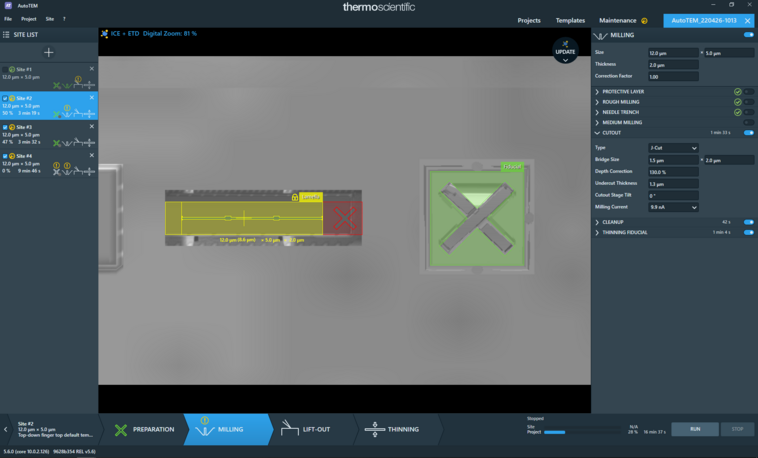

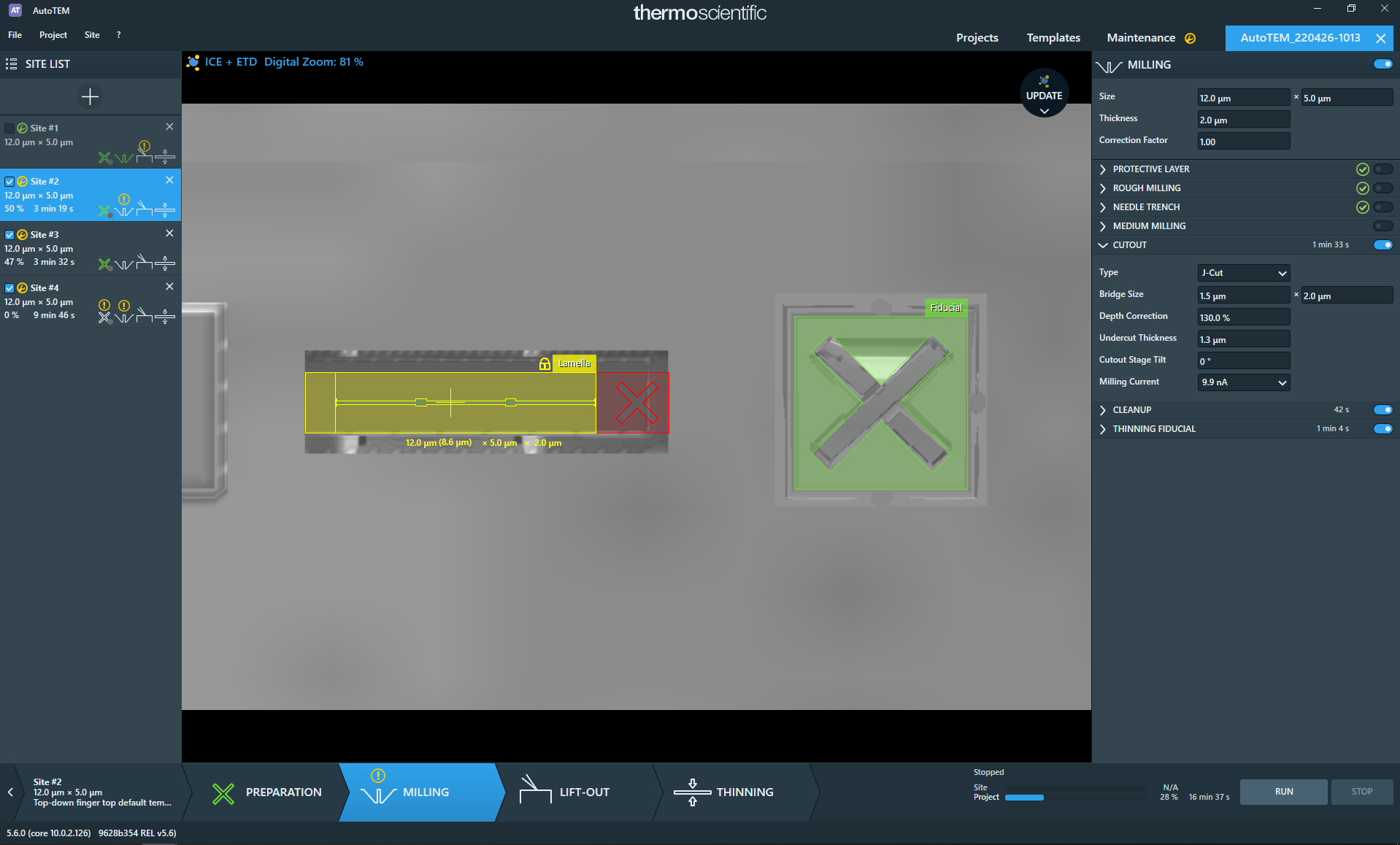

Although it may seem misleading the AutoTEM is an application running on a special SEM microscope equipped with so-called ion cannon in addition to standard detectors and a source of electron radiation. Gallium ions are very heavy and their rectified beam thus enables "cutting" into a sample or transferring the cut parts by welding onto a so-called needle. So, the AutoTEM is an application for automatic sample preparation for TEM (transmission) electron microscopes. It is used for the preparation of so-called lamellas (a sample wafer with a thickness of about 100 nm), both in the field of biology and especially in the semiconductor industry. Just to give you an idea of how accurate the AutoTEM must be: the diameter of a human hair is between 18 and 180 μm. The diameter of a red blood cell is roughly 7.5 μm. As for processors, there can be on the order of ten thousand transistors on one square nanometre. This means that we would stack about 440 billion transistors on one red blood cell. The AutoTEM software together with a dual electron microscope can prepare a sample of even such a small transistor.

-

5x6 array of lamellas ready to be lifted out.

-

A sectioned lamella that will thin and polish.

-

Finished lamella.

-

Specification of the resulting lamella in AutoTEM.

Customer Feedback _

„Edhouse is our strategic SW development partner more then 15 years. With Edhouse, we've experienced excellence in quality, on-time project completion, and continuous innovation. Thermo Fisher Scientific is delivering high-tech systems serving science, and SW development has a big overlap with physics and integration of high-tech low-level components. At the same time, our products are used by experts to simplify their work. Edhouse is successfully working with us in this unique environment, enabling our customers to make the world healthier, cleaner and safer.“

Filip Matuška Director Software – Thermo Fisher Scientific